How Mining Submersible Pumps Support Dewatering in Open-Pit and Underground Operations

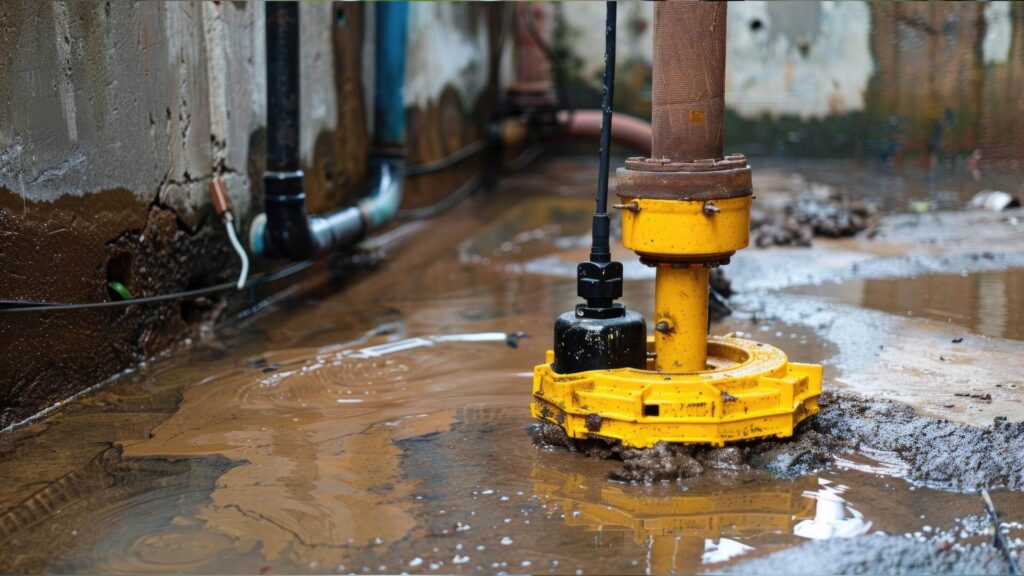

Effective water management stands at the core of profitable and safe mining. Whether a site is carved into a mountainside or extends deep beneath it, uncontrolled groundwater and storm runoff can halt production, destabilize workings, and inflate maintenance budgets. Modern mining submersible pumps have emerged as the workhorse of dewatering strategies, operating directly in flooded zones to move high volumes of sediment-laden water without constant operator intervention. Their compact design, rugged materials, and automated controls make them indispensable in both open-pit pits and the confined headings of underground mines, where space, access, and uptime are at a premium. By positioning the pump at the water source rather than above it, operators eliminate priming issues, reduce suction losses, and cut energy consumption. The result is a safer pit wall, drier haul roads, and stable underground headings, all of which translate into fewer stoppages and measurable cost savings. In short, mining submersible pumps are not just a dewatering tool; they are an operational safeguard that underpins productivity across the entire life of a mine. The Role of Dewatering in Mining Operations Water Challenges in Open-Pit vs. Underground Mines Open-pit operations must contend with direct rainfall, stormwater sheet flow, and seepage through fractured geology. Left unchecked, ponding water softens haul-road surfaces, increases rolling resistance, and accelerates tire wear on heavy equipment. Underground mines face a distinct threat profile, including aquifers intersected during development, pressurized fissures, and seasonal inflows that can flood declines and shafts. In both settings, stagnant water corrodes structural steel, short-circuits electrical infrastructure, and compromises slope or roof stability, risks that escalate maintenance costs and expose crews to hazards. Why Dewatering Is a Critical Operational Priority Every unplanned stop to pump out flooded headings translates directly into lost ore tonnage and revenue. Proactive dewatering ensures that drills, loaders, and conveyors operate on schedule, keeping the mine’s production curve on target. Moreover, regulators are increasingly mandating active water-management plans that prevent the discharge of contaminated runoff into local waterways. Deploying submersible pumps for mining sector compliance not only protects the environment but also shields operators from fines and reputational damage. Finally, efficient water control underpins asset longevity. Dry mechanical chambers, electrical rooms, and haul routes reduce corrosion, extend component life, and decrease the frequency of overhauls. Here, rugged submersible mining pumps deliver consistent flow rates and abrasive-handling capability that alternative surface units cannot match, sustaining both safety metrics and bottom-line performance. What Are Mining Submersible Pumps and Why Are They Ideal? Modern mining submersible pumps are purpose-built centrifugal units whose motors and hydraulics are sealed within a water-tight housing, allowing the entire assembly to run fully submerged at the fluid source. By removing the suction lift altogether, these pumps maintain a constant prime, reduce NPSH concerns, and deliver stable flow under fluctuating heads, capabilities that conventional skid or trailer units struggle to match in dynamic mine conditions. Key Design Features of Submersible Mining Pumps Advantages Over Other Pump Types Dewatering in Underground Mining: Systems and Submersible Pump Applications Components of an Underground Dewatering System Engineering teams typically combine drilled vertical wells that lower piezometric pressure, horizontal drains that intercept face inflows, rock-bolted collection gutters, and strategically located sumps to manage groundwater. These sumps channel water toward either single-stage submersible pumps for mining sector duties or multistage booster strings that lift water hundreds of metres to the surface. Vacuum lines and sensors integrate into the mine’s SCADA system, allowing operators to view inflow trends in real-time. How Submersible Pumps Fit In Placed at each low point, mining submersible pumps automatically start when float switches detect rising water. The pumps’ recessed-vortex or semi-open impellers clear grit, cutting chips, and shotcrete spatter without clogging, a critical advantage as crews blast and muck out headings. Because thermal sensors and moisture probes are embedded in the stator, the mine control room can receive an alarm long before a bearing overheats or a seal fails, allowing technicians to service the unit during planned downtime. For deeper shafts, chains of submersible mining pumps staged at intermediate levels overcome static head while simplifying hose routing and power supply. Safety and Efficiency Benefits By extracting water at its point of accumulation, submersible pumps for mining sector operations keep footwall travelways dry, reducing slip incidents and allowing diesel and electric LHDs to maintain design speeds. Clear working faces enable accurate drill-and-blast patterns, while dry explosives remain stable and predictable. Importantly, workers spend less time in flooded areas setting temporary pipework; a single hook, power cable, and lay-flat discharge are all a crew needs to reposition submersible mining pumps as the mine advances. Continuous, automatic dewatering maximises face time, minimises electrical downtime, and preserves ground support integrity across every shift. Open-Pit Dewatering: The Open Sump Pumping Method In an open-pit mine, rainfall, groundwater seepage, and wash‐down water all gravitate to the lowest benches. Operators excavate purpose-built sumps at these points and install mining submersible pumps directly inside the collection pit. Because the pump and motor are submerged, flow begins immediately and continues even as water levels fluctuate, keeping haul roads passable and pit walls stable. How It Works – As water drains into the sump, sensors or float switches trigger the pump to lift the inflow through a lay-flat hose to a settling pond or discharge header well outside the excavation zone. The self-priming nature of mining submersible pumps eliminates the need for vacuum assist systems, allowing crews to deploy extra units within minutes when a monsoon front or sudden storm threatens production. For contractors seeking rapid deployment, submersible pumps for mining sector applications offer a plug-and-play solution that integrates seamlessly with existing power distribution skids. Where Submersible Pumps Excel – Unlike skid-mounted units that crowd bench space, the slim profile of mining submersible pumps allows them to sit flush with the pit floor, leaving runways clear for trucks and loaders. As the excavation deepens or shifts laterally, a crane simply lifts the unit, repositions the discharge line, and drops it back into the newly cut sump, preserving optimal head pressure. When

How Mining Submersible Pumps Support Dewatering in Open-Pit and Underground Operations Read More »