Dredging Equipment Selection: Understanding Pump Capacity and Cutter Power

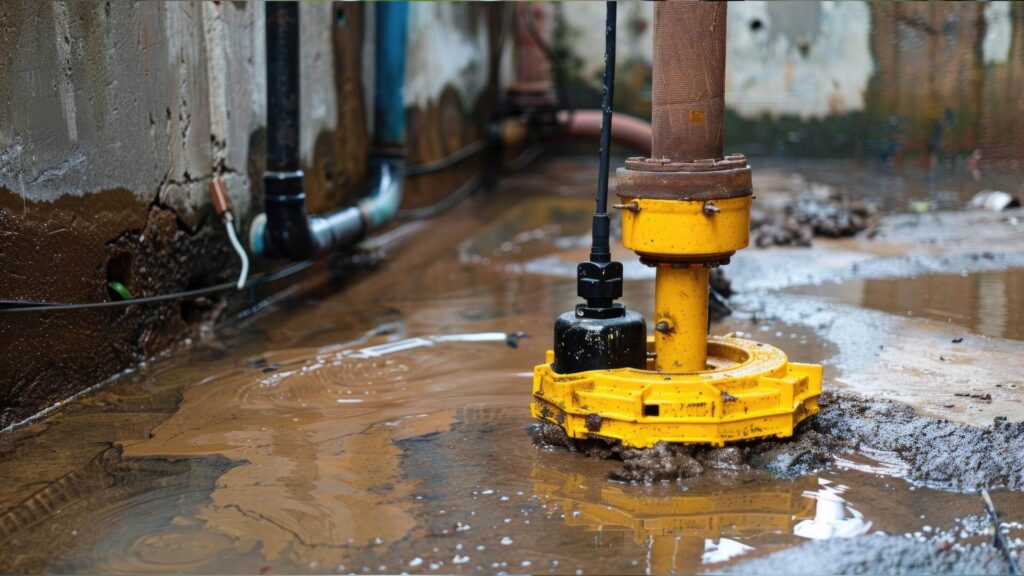

Dredging is an essential process in excavation and sediment removal, playing a crucial role in maintaining waterways, restoring shorelines, and enabling construction projects. Whether it’s for mining, environmental restoration, or port maintenance, selecting the right dredge equipment is vital for achieving efficiency and cost-effectiveness. Each dredging project presents unique challenges, requiring careful consideration of equipment specifications to ensure optimal performance. One of the most critical aspects of selecting dredge equipment is understanding the relationship between pump capacity and cutter power. These two factors directly impact the efficiency of sediment removal, the depth and type of material that can be dredged, and the overall productivity of the operation. An inadequate pump can lead to inefficient material transport, while an underpowered cutter may struggle with compacted or coarse sediments. Ensuring a proper balance between these components helps maximize dredging efficiency and reduce operational costs. For smaller-scale projects, such as pond dredging equipment, choosing the right combination of pump and cutter power is equally important. Smaller bodies of water often contain fine sediments, organic material, and debris, requiring specialized equipment to prevent blockages and maintain consistent performance. Understanding how pump capacity and cutter power influence dredging results is key to selecting the most effective solution for any project. Understanding Dredging Equipment and Its Key Components Overview of Dredging Equipment Dredging equipment removes sediment, debris, and unwanted materials from bodies of water such as rivers, lakes, harbors, and ponds. This process is critical for maintaining navigability, preventing flooding, and restoring ecosystems. Several types of dredge equipment are available, each designed for specific applications. Cutter suction dredgers are widely used for large-scale operations where hard or compacted sediments need to be broken up before being transported through a pipeline. Auger dredgers, on the other hand, are well-suited for precision dredging, making them ideal for environmental projects or pond maintenance. Hopper dredgers are designed for deepwater excavation, collecting sediment in onboard storage before relocating it elsewhere. Pond dredging equipment is commonly used to remove accumulated sediment in residential, industrial, and agricultural ponds for smaller-scale operations. These systems are often compact and designed to operate in shallow waters, ensuring effective sediment removal without disturbing the surrounding ecosystem. Selecting the right dredge equipment depends on factors such as the type of material to be removed, project scale, and environmental considerations. Key Components of Dredging Equipment Dredge Pump The dredge pump is the heart of any dredging system, responsible for transporting sediment and water through pipelines. A high-quality pump ensures efficient material movement with minimal downtime. Pump capacity is crucial in determining the volume of solids that can be moved per hour, directly impacting overall dredging efficiency. Cutter Head or Auger The cutter head or auger breaks up sediment before it is pumped away. Cutter heads are typically used in cutter suction dredgers to excavate harder materials, while augers provide more controlled sediment removal. Thus, they are particularly useful in pond dredging equipment and environmental dredging applications. Power Systems Hydraulic or electric systems can power dredging equipment. Hydraulic power provides greater force, making it ideal for heavy-duty dredging, while electric-powered systems are often more energy-efficient and environmentally friendly. Pipeline and Discharge Systems Pipelines transport dredged materials from the excavation site to the designated discharge area. The efficiency of sediment transport depends on factors like pipeline diameter, pump pressure, and sediment composition. A well-designed pipeline system ensures smooth operations and minimizes blockages, reducing maintenance requirements. Understanding Pump Capacity in Dredging Operations What Is Pump Capacity? Pump capacity refers to the volume of water and sediment a dredging system can move within a given timeframe. It is one of the most critical factors in dredging operations, directly affecting efficiency, productivity, and overall project success. The right pump capacity ensures that dredge equipment can effectively transport sediment without excessive wear or energy consumption. Several factors influence pump capacity, including flow rate, head pressure, and efficiency. Flow rate is the amount of material the pump can move per unit of time, typically measured in gallons per minute (GPM) or cubic meters per hour. Head pressure refers to the resistance the pump must overcome to move sediment through pipelines, influenced by pipeline length, diameter, and elevation changes. Efficiency measures how well the pump converts power into effective sediment transport, impacting operational costs and equipment longevity. How to Determine the Right Pump Capacity Choosing the appropriate pump capacity requires a detailed assessment of the dredging project. One of the first considerations is the type of sediment being removed. Fine sand and silt require different pump capabilities than heavy clay or coarse gravel. Understanding the material composition ensures that the pump can handle the project’s specific demands without clogging or excessive wear. Another key factor is matching pump specifications to project needs. Dredge equipment used for large-scale operations, such as mining or harbor maintenance, requires high-capacity pumps to manage significant sediment loads efficiently. On the other hand, pond dredging equipment is designed for smaller-scale projects, where a lower-capacity pump may be sufficient to remove accumulated organic material and fine sediments without overburdening the system. Common mistakes in selecting pump capacity include underestimating sediment type, choosing an oversized pump that wastes energy, or using a pump with insufficient head pressure. These errors can lead to inefficiencies, increased costs, and premature equipment failure. Impact of Pump Capacity on Performance An underpowered pump can result in slow dredging operations, frequent clogs, and excessive downtime. Conversely, an oversized pump may consume unnecessary fuel and increase wear on dredge equipment components. Balancing pump capacity with project needs optimizes efficiency, reduces fuel consumption, and extends equipment lifespan. For example, pond dredging equipment with the right pump capacity can operate continuously without overwhelming the system, ensuring effective sediment removal with minimal maintenance. Real-world case studies demonstrate that selecting the correct pump can improve dredging speed, lower operational costs, and enhance overall project efficiency. Cutter Power and Its Role in Dredging Efficiency What Is Cutter Power? Cutter power refers to the force applied by the cutter head or auger to break up and

Dredging Equipment Selection: Understanding Pump Capacity and Cutter Power Read More »