Introduction

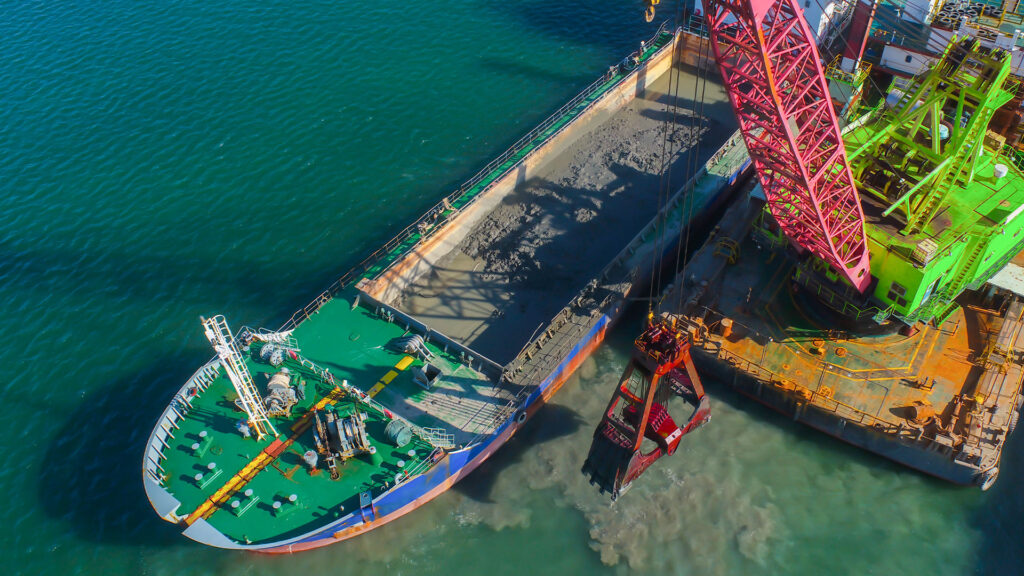

Coastal regions in the Philippines are dealing with rapid erosion, heavy sedimentation, and recurring floods that disrupt ports, urban communities, and development projects. Traditional equipment is no longer enough to manage these conditions, especially as waterways fill up faster and storm events become more frequent. This is where modern dredging technology becomes essential. For contractors, LGUs, and engineering teams, choosing the right Philippines dredging equipment is a direct investment in long-term shoreline stability, safer waterways, and stronger coastal resilience.

Why coastal resilience dredging needs a Rethink in the Philippines

Across many Philippine coastal areas, dredging for coastal resilience is still viewed as a cleanup activity undertaken only when waterways become too shallow or a flood incident requires action. The problem is that the coastal environment has changed. Sediment is moving in greater volumes, storms are reshaping inlets more quickly, and channels that once remained stable for years now require attention within a single season.

As a result, dredging is no longer just maintenance. It is a planning decision that directly affects how quickly a port recovers after a typhoon, how reliably a river system drains during peak rainfall, and how safe reclaimed or low-lying zones remain as silt begins to accumulate again.

The Philippines dredging equipment capability has become a core part of resilience planning. Older machines struggle to keep up with new sediment loads, tighter project schedules, or deeper draft requirements for modern vessels. Newer systems can operate in shallow and congested sites, deliver higher output with lower downtime, and maintain steady productivity during high-risk months.

This is where Dredge & Pump Pros Philippines fits into the shift. They supply equipment designed for the actual conditions contractors and LGUs face in the field. That includes unpredictable silt types, narrow river corridors, mixed-use coastlines, and weather interruptions that require fast mobilization and reliable pumping power. Their product range is built for real-world project constraints rather than ideal scenarios, exactly what coastal resilience work needs today.

What a Resilience Focus Actually Delivers

When coastal resilience dredging is treated as a resilience function rather than a one-off clearing task, the results become measurable and better aligned with long-term infrastructure goals. The impact is not abstract. It shows up in how quickly a channel drains during heavy rainfall, how consistently a port remains accessible to vessels, and how stable a shoreline remains once silt movement is controlled.

For contractors and LGUs, the biggest shift is in predictability. Projects become easier to schedule because dredging cycles are planned based on data instead of emergencies. Flood risks in critical areas can be reduced because waterways maintain their designed capacity. Port operators experience fewer disruptions because draft depth remains steady even during peak sediment movement months.

This approach depends heavily on the equipment behind the work. High-output pumps and efficient dredging systems reduce the need for repeated mobilization. Machines built for Philippine conditions can manage both soft silt and compacted material without long downtime. Suppliers like Dredge & Pump Pros Philippines provide these capabilities through pumps, dredgers, and modular systems that support continuous operations. The outcome is a dredging program that delivers resilience benefits with fewer interruptions and lower operational uncertainty.

The Modern Toolbox That Actually Solves Philippine Coastal Problems

Many project teams assume all Philippines dredging equipment works the same way. In reality, the performance gap between older units and updated systems is significant, especially given the ongoing changes in the Philippines’ sediment profile and weather patterns. Modern dredging technology is not about having fancier machinery. It is about having tools that match real-site conditions: access is tight, sediment layers shift quickly, and continuous operation is required even in unpredictable weather.

Modern Philippine dredging equipment is essential because most waterways cannot tolerate slow output or frequent breakdowns. Sediment here often moves in mixed layers, from soft silt near river inlets to compacted material closer to ports and reclamation sites. Outdated machines lose efficiency as soon as material changes. Newer systems are built to adjust output and maintain steady pumping flow even when sediment loads vary from hour to hour.

This is where three core technologies make a measurable difference.

Cutter suction systems for consolidation zones

Channels that collect compacted or previously dredged material require solid cutting power. Updated cutter systems can break material consistently without long pauses for repositioning. This is important for bottleneck sections where narrow waterways continue to fill and slow downstream flow. Older models struggle here because cutting torque and pumping efficiency often drop under heavier loads.

High-efficiency slurry and submersible pumps for shallow and restricted sites

Many Philippine dredging sites are located within narrow river corridors or near built-up shorelines, where full-sized dredgers cannot maneuver. High-efficiency pumps become the practical option because they can be deployed with floats or mounted directly on excavators. They move large volumes with smaller crews and shorter mobilization times. Dredge & Pump Pros Philippines specializes in these systems and supplies pumps designed for variable sediment conditions, which reduces delays caused by clogging or uneven flow.

Modular and scalable platforms for environments that change quickly

Storm seasons reshape inlets and river mouths almost every year. Fixed dredging configurations become inefficient because the water depth and access points shift. Modular pontoons and scalable dredge frames enable contractors to quickly reconfigure their setup and continue operations even as the site layout changes. This reduces standby time, a major cost driver in coastal projects.

Modern technology is not about replacing what teams already know. It is about enabling consistent output in areas where traditional machines experience productivity losses. For Philippine coastal resilience work, this consistency is often the difference between a dredging project that maintains long-term safety and one that requires constant rework.

Matching Technology to Philippine Site Conditions

Most dredging failures in the Philippines do not come from poor planning. They come from using the wrong equipment for the sediment type or the site layout. Conditions shift fast here. Riverbeds are unpredictable; tidal influence can alter the material profile within hours, and many coastal sites have limited access for heavy equipment. A simple equipment mismatch can produce weeks of delays or force repeated rework.

Here is how modern technology aligns with common project scenarios nationwide.

River mouths with fast siltation

These areas usually contain soft to medium material that repeatedly returns with each tide. High-efficiency submersible pumps are best suited here because they maintain a steady flow even when sediment is light and unstable. They also set up quickly, which is critical when tidal windows are short. Dredge & Pump Pros Philippines often provides modular pump setups for this exact situation, helping teams avoid long mobilization times.

Shallow estuaries and urban waterways

Access is limited, and maneuvering space is tight. Cutter systems are not always ideal because the draft is too shallow. Excavator-mounted pumps or floating pump units are more practical. They enable operators to reach narrow corners that previously required manual cleanup. These setups deliver consistent output without requiring a full dredger footprint.

Reclamation zones and port expansion areas

Material here is usually compacted or layered. A cutter system is essential for breaking and moving material without compromising performance. Updated cutter heads handle variable density better than older versions, which prevents clogging during transitions between soft and compacted layers. When paired with high-output pumps from suppliers such as Dredge & Pump Pros Philippines, contractors can maintain production rates that meet project timelines.

Shoreline reinforcement and beach recovery

These projects rely on controlled material placement. Hopper systems or pump-based transfer setups are useful because they provide greater discharge precision. The goal is not just removal but also redistribution, and modern pumping systems provide greater control over distance and volume.

Matching equipment to the site is no longer optional. Philippine coastal environments change too quickly for trial-and-error. Modern dredging technology provides contractors with predictable performance even when material and layout conditions change, which is essential for coastal resilience outcomes.

Micro Case Scenarios from Philippine Coastal and River Projects

Real progress in coastal resilience comes from small operational wins. The following scenarios reflect common challenges faced by Philippine contractors, LGUs, and port operators. Each example shows how updated Philippines dredging equipment changes the outcome and prevents recurring problems that older systems cannot handle.

A river channel that floods every monsoon

A mid-sized municipality along a major river experiences annual flooding because the channel shoals before the rainy season. Traditional cleanup activities use small excavators and pumps that cannot handle the sediment load. The waterway fills up again within weeks.

A shift to high-efficiency submersible pumps allows the team to remove larger volumes in shorter cycles. The pumps handle both soft and medium-density materials without clogging, reducing downtime. With guidance from Dredge & Pump Pros Philippines, the municipality sets a fixed pre-season dredging window. Flood levels drop the following year because the channel maintains sufficient depth for peak rain events.

The shoreline that erodes after every storm surge

A coastal town depends on tourism but struggles with recurring sand loss. Previous attempts to restore the beach involved moving material manually or using small loading equipment, which did not address offshore sediment buildup.

A contractor proposes a pump-based transfer system to transport material from offshore sand deposits back to the beach zone. The controlled discharge helps rebuild the profile evenly. Updated pump technology improves control over distance and placement, which reduces rework. The town gains a more stable shoreline that protects nearby infrastructure during storm season.

Port approach that requires repeated emergency dredging

A provincial port sees heavy siltation near its approach channel. Vessel schedules are frequently disrupted because depth drops below safe draft levels. Older cutter units struggle with compacted layers, which forces operators to run slower than planned.

A modern cutter system paired with a high-output pump increases production without increasing the operation’s footprint. The contractor completes the required depth restoration on schedule and with fewer interruptions. The port moves from reactive dredging to a predictable maintenance plan. The Philippines dredging equipment reliability gives port management the confidence to schedule larger vessels during peak months.

These micro cases reflect a common pattern. The problem is rarely the strategy. The equipment cannot deliver the required output for the Philippine sediment behavior. Modern dredging technology changes that by providing consistent power, faster mobilization, and flexibility for tight or shifting environments.

What Buyers Should Check Before Procuring Philippines Dredging Equipment

Many dredging projects in the Philippines face delays because the selected equipment does not align with site conditions or long-term operational needs. Procurement teams often review paper capacity numbers but overlook factors that determine whether the machine will perform as expected under local conditions. A clear checklist makes the evaluation process easier and reduces costly mismatches.

Verify the actual pumping output under mixed sediment.

Paper specifications do not reveal how a pump handles sudden changes in material density. Many Philippine waterways contain soft silt in the upper layer and compacted material below. Buyers need equipment that maintains a stable flow through these shifts. Pumps supplied by Dredge & Pump Pros Philippines are designed to handle this behavior and deliver more predictable output in mixed-sediment environments.

Check access requirements at the project site.

Large dredgers may look attractive on spec sheets, but tight river corridors, shallow estuaries, and built-up shorelines make them impractical. Modular pontoons, submersible pumps, or excavator-mounted systems often deliver better results. Procurement should map the exact access limitations before selecting a machine.

Review maintenance and parts availability within the country

Downtime is one of the biggest cost drivers in dredging work. Machines that depend on imported parts or delayed service support can stall entire projects. Local availability of parts and technical service is crucial. This is an area where Dredge & Pump Pros Philippines gives buyers a practical advantage, as its support structure is based locally.

Evaluate mobility and setup time.

Weather interruptions in the Philippines often create short operational windows. Equipment that takes too long to reposition or restart will lose productivity. Modern pump systems and modular dredgers reduce setup time and allow teams to resume work quickly after weather delays.

Clarify compliance requirements before procurement.

Environmental agencies require clear documentation for plume control, discharge points, and disposal handling. Buyers need equipment that meets these conditions without requiring excessive field adjustments. Choosing technology with controllable output and predictable flow makes the approval process easier and reduces compliance risks during operations.

A procurement plan built on these checks results in fewer surprises on site. It also ensures that the Philippines’ dredging equipment supports long-term resilience goals rather than becoming a recurring operational bottleneck.

How to Justify Investment in Modern Philippines Dredging Equipment

Most coastal and river projects in the Philippines struggle to secure funding, not because there is no budget, but because the returns from dredging are hard to explain in financial terms. The work is essential, yet the impact is often invisible until something goes wrong. A clearer way to justify the investment is to frame dredging as a cost avoidance tool rather than an expense.

Calculate avoided damage instead of focusing only on equipment cost.

Flooding, port operations disruptions, and shoreline retreat cause measurable financial losses. LGUs face emergency spending and property damage. Port operators deal with vessel delays and reduced throughput. When modern dredging technology prevents these disruptions, the investment pays for itself. Procurement teams can present this as the difference between planned cost and unplanned emergency spending.

Quantify the impact of the reliable production rates.

Older machines struggle to maintain consistent output, especially in mixed sediment. This inconsistency extends project timelines and increases fuel, labor, and monitoring expenses. Updated equipment from Dredge & Pump Pros Philippines delivers more predictable production rates. Predictability reduces overtime costs and limits mobilization cycles, which often account for a large share of project spending.

Modern dredging technology is not an optional upgrade. It is a requirement for coastal infrastructure to remain functional amid increased sediment transport and more frequent extreme weather events. Once quantified, the financial case becomes clear and defensible.

Operational Practices That Keep Philippine Dredging Projects on Track

Even the best Philippines dredging equipment cannot deliver full results without a reliable operational approach. Philippine coastal and river conditions change quickly, so teams need methods that maintain productivity and avoid rework. The following practices help projects stay on schedule and make better use of modern dredging technology.

Plan around seasonal windows, not fixed calendars.

Monsoon cycles, high-turbidity periods, and tidal shifts significantly affect productivity. Teams that plan dredging on rigid timelines often lose days due to unsuitable conditions. A project schedule based on seasonal windows enables operators to deploy equipment when sediment is most stable, and water conditions support efficient pumping. This reduces fuel use and prevents unnecessary standby costs.

Run sediment testing before finalizing the equipment.

Some sites contain layered material that changes within short distances. Testing helps determine whether the project will require cutting capability, high-flow pumping, or a mixed setup. A small investment in testing prevents larger losses from equipment mismatch. This is also where suppliers like Dredge & Pump Pros Philippines can guide teams in selecting the appropriate configuration based on sample results.

Use adjustable setups for sites that shift after storms

Many channels and inlets alter their shape after heavy rainfall or storm surges. Modular pontoons and pump systems enable contractors to reposition quickly, without the weeks of remobilization required by conventional systems. Flexible setups also support partial operations when only one section of the site becomes accessible.

These practices reduce operational uncertainty and allow modern Philippines dredging equipment to perform at its best. Philippine coastal resilience projects deliver the greatest value when equipment capabilities and site management are aligned.

Conclusion

Coastal resilience in the Philippines depends on how effectively projects manage fast-moving sediment, changing site conditions, and stricter regulatory requirements. Traditional approaches are no longer sufficient because waterways and shorelines are shifting too quickly, and operational risks are higher than before. Modern dredging technology provides the consistency and control needed to keep channels open, protect infrastructure, and reduce extended rework.

For contractors, LGUs, and port operators, the practical advantage lies in choosing equipment that matches real-world field conditions. Reliable pumping output, flexible configurations, and strong local support now play a direct role in the success of coastal and river projects. Suppliers like Dredge & Pump Pros Philippines help teams meet these requirements by providing Philippines dredging equipment, built for the environments of the country, and by supporting operators through every stage of the work.

A single major project does not achieve coastal resilience. It is achieved through steady, predictable dredging performance across many seasons. Modern equipment enables project owners to achieve that level of consistency and ensures that coastal communities, ports, and economic zones remain protected as conditions continue to change.